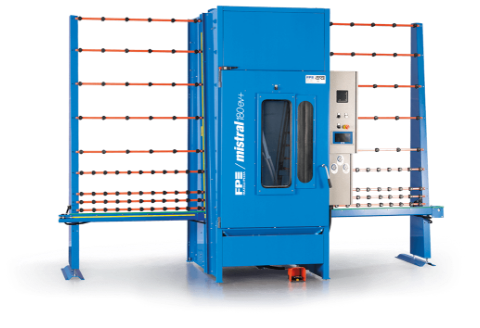

MARKING MACHINES

FOR GLASS AND

MIRRORS

ORIGINAL

SPARE PARTS

To ensure a high quality standard of our after-sales service, we maintain a wide stock of original spare parts and consumables ready for quick shipment.

The result you want to achieve

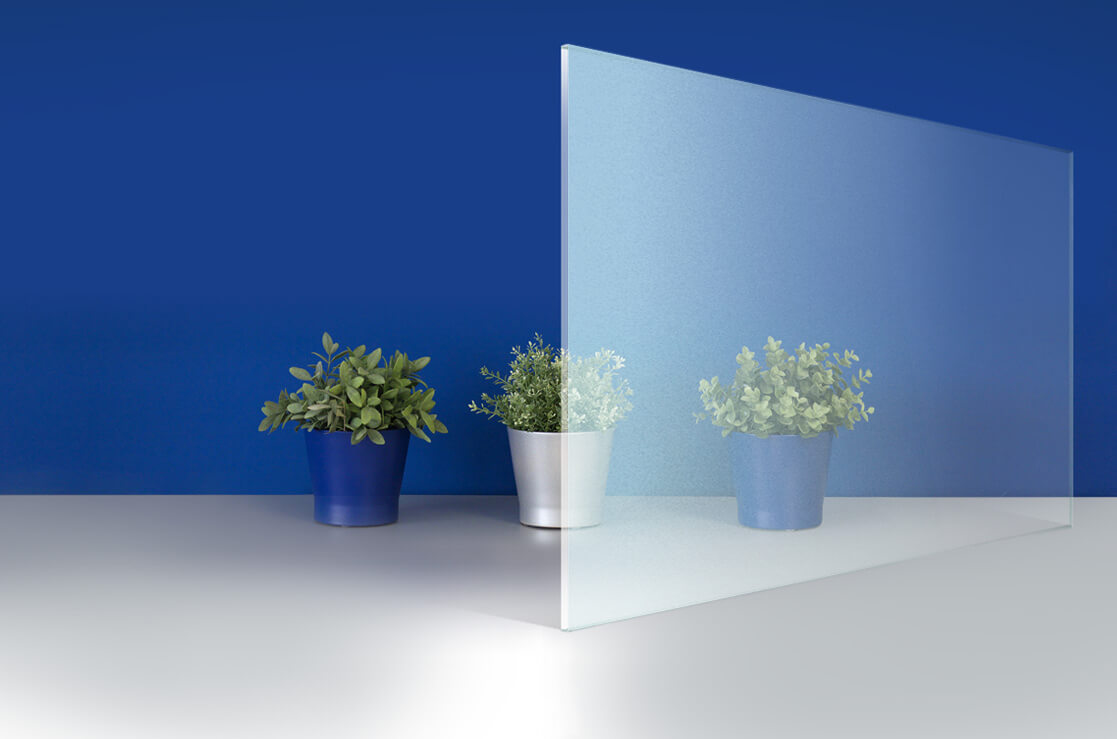

NORMAL

WITH:

NORMAL

SHADING

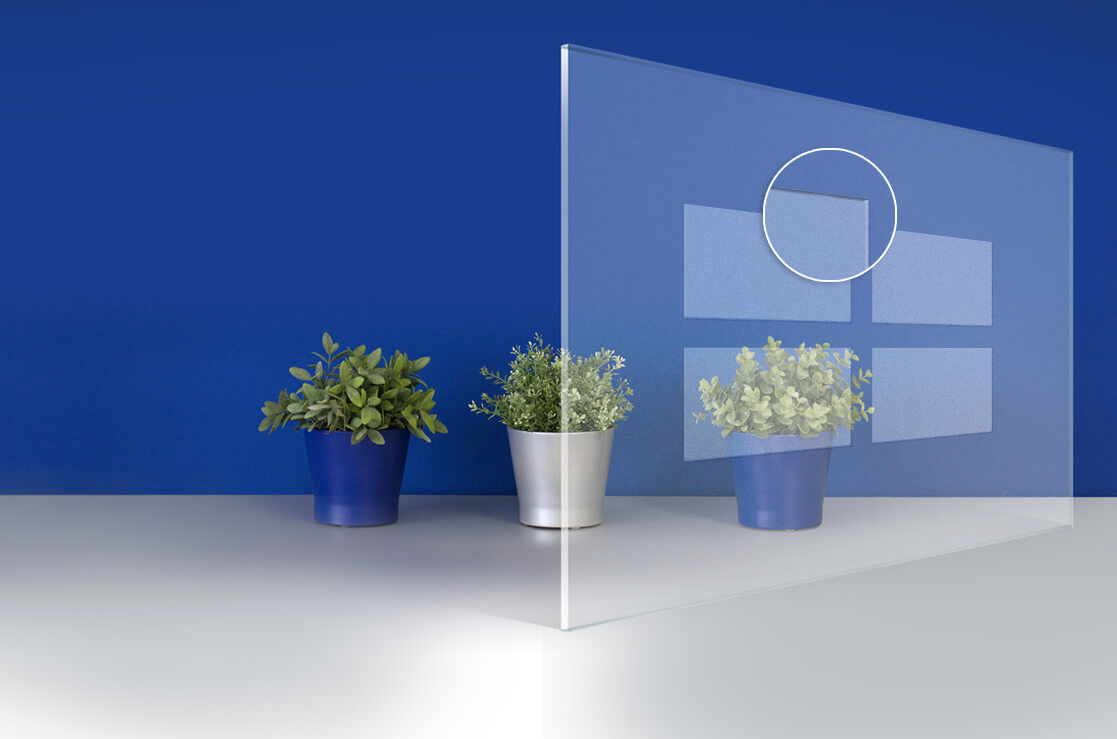

WITH:

LIGHT

WITH:

CENTRAL

SHADING

WITH:

ENGRAVED

WITH:

PROGRESSIVE

ENGRAVED

WITH:

DECORATIVE

WITH:

differentiated

zones

WITH:

FRATELLI PEZZA

exporting countries

FRATELLI PEZZA

machines sold

FRATELLI PEZZA

BUsiness partners

FRATELLI PEZZA

years' experience

FRATELLI PEZZA

FAMILY HISTORY THAT CONTINUES

Fratelli pezza

News

Second-hand Glass Sandblasting Machines: When to choose them and how to use them

In the glass processing industry, every investment directly impacts a company’s competitiveness. Purchasing an industrial sandblasting machine is not merely a technical decision, but a strategic one that influences process quality, production efficiency, and medium- to long-term growth. In many ca

Functional surfaces and sandblasting: new ways of understanding and working with glass

In 2026, glass processing definitively enters a new phase. Glass is no longer considered solely in terms of sheets, thicknesses or levels of transparency, but as a complex design surface, capable of interacting with light, people and the surrounding environment. As the market perspective changes, so

High-end glass doors: why leading manufacturers are investing in sandblasting, marking and protective coatings

In the high-end entrance door and premium window sector, glass is taking on an increasingly strategic role. In many cases, it is no longer just a functional component but a decorative surface capable of adding significant value to any environment or building and of defining the style of an entire co